For Any Product Inquiry or Information Contact Us.

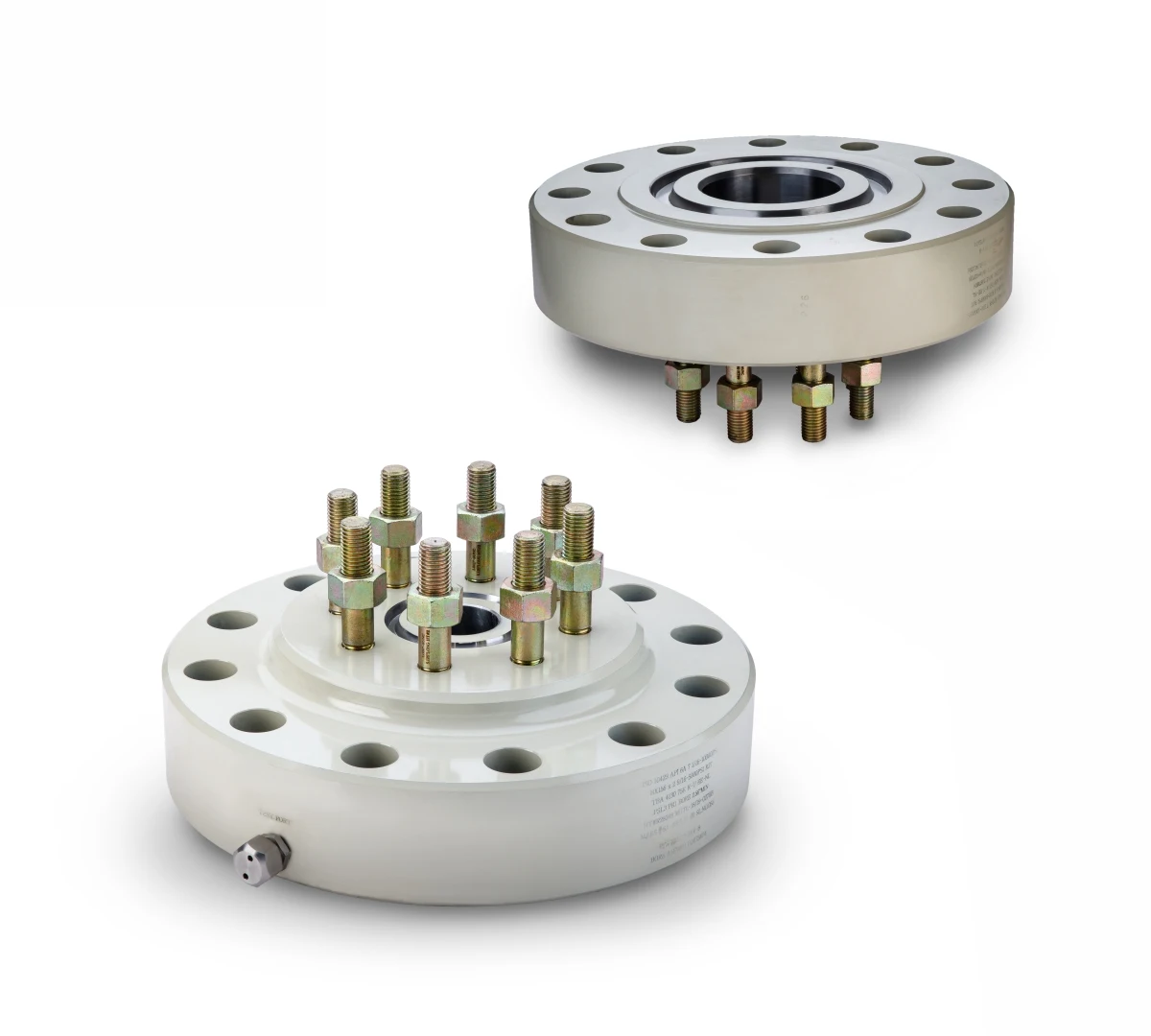

We have the ability to produce quality engineered solutions, in many areas of high and low pressure containment and control.Our Company Certifications

About Mars Forge Private Limited

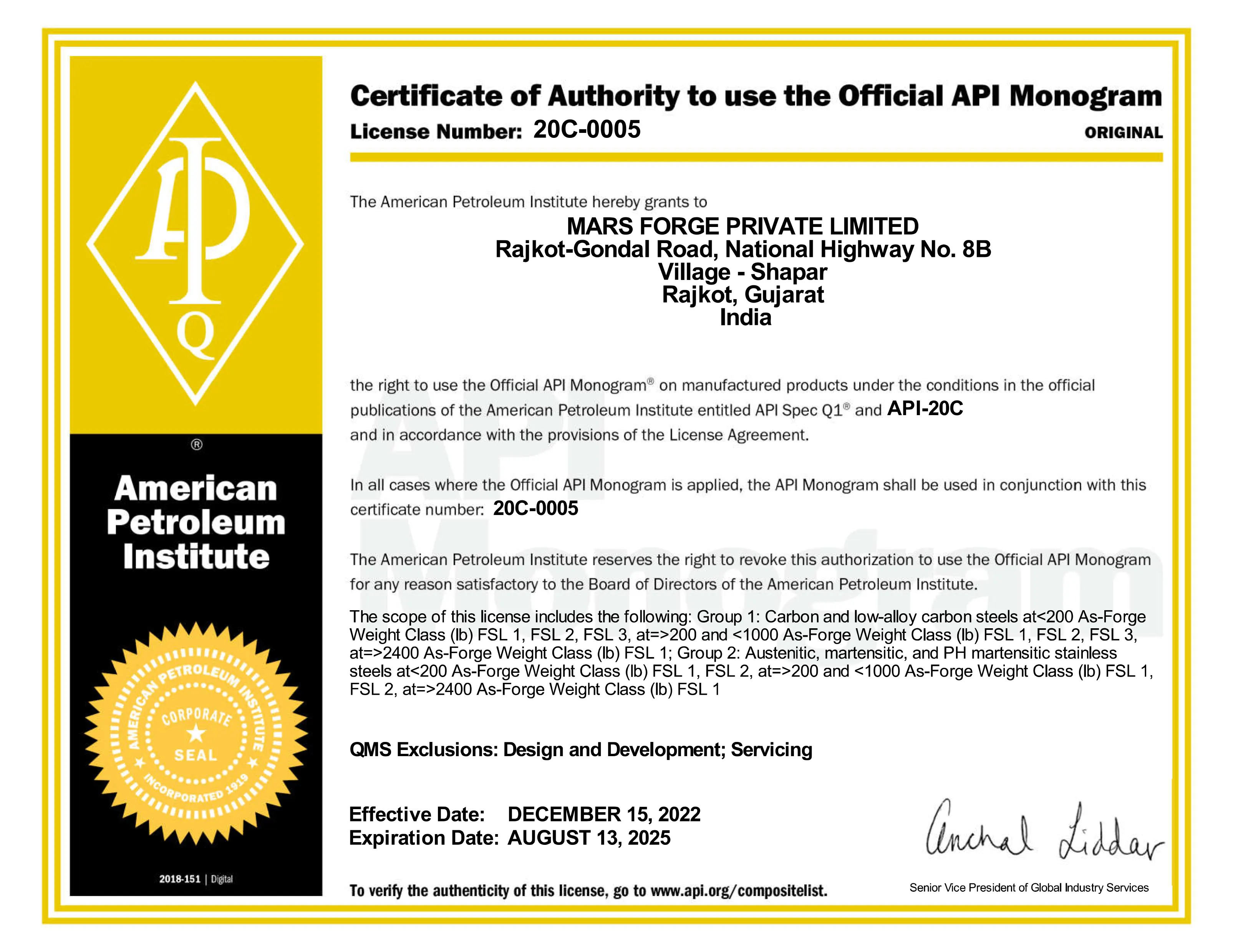

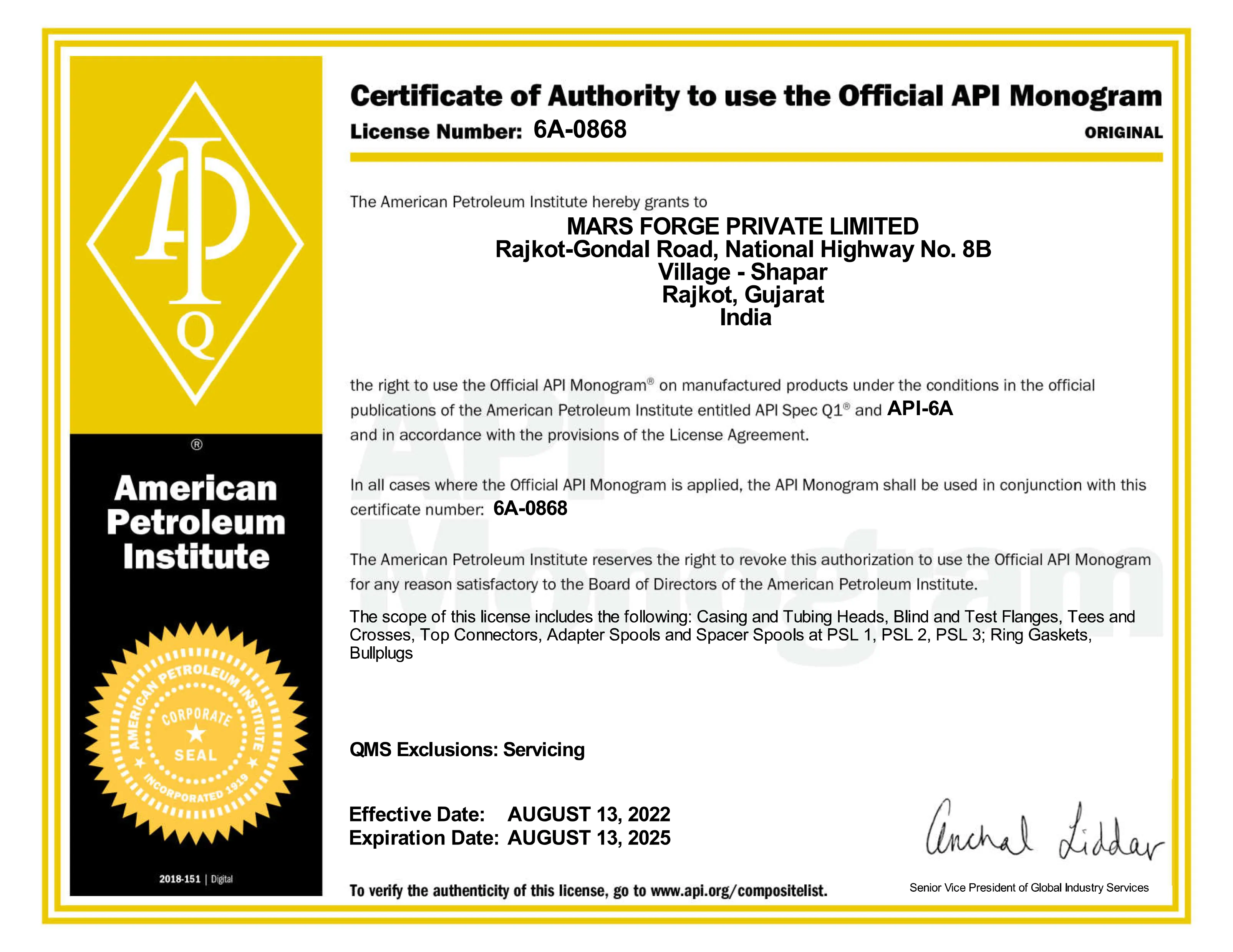

Mars Forge Pvt. Ltd. started our journey in manufacturing forged components in 1989. Since then we have catered to Oil & Gas, Auto, Diesel Engines, Energy and various other engineering sectors. We are proud to announce that we are the only company in India to have API 6A Monogram License clubbed with API 20C Monogram License in a single unit.

At Mars Forge, we understand that our customers, face an increasingly complex business environment, where excellence is constantly being futher refined and the margins for error are shrinking by the hour. We understand that sophisticated forgings form the backbone of our customer's enterprise.

At Mars Forge, superior engineering, state-of-the-art equipment, committed human resources, and an unflinching commitment to excellence all converges to providing our customers with a vital asset.

Our All Facilities

Cutting Shop

Capacity to saw upto Diameter of 500 mm with 12 bandsaw machines and 1 shearing machine.

Closed Die Forge Shop

Capacity to forge single part upto 250 kgs with pneumatic hammers of 6 tonne and 3 tonne capacity and mechanical hammer of 2 tonne capacity.

Die shop

Capacity to machine die size upto 900 (W) x 1500 (L) x 700 (T) mm with weight of 15 tons with the assitance of 2 VMC's and other conventional machines.

Machine Shop

Capacity of turning diameter of upto 600 mm and length upto 1.5 meters complemented with upto 600 mm table dimensions of HMC's and upto 5 axis of VMC's as well.

Heat Treatment

Fully automated Continuous type Furnace with facility of Hardening and Tempering with Hardness Testers of Brinell as well as Rockwell available in house.

Metullurgy Lab

Fully equiped Lab with Tensile, Impact (ASTM), Micro as well as Macro testing facility available.

NDE Testing

Dedicated personnel upto ASNT NDT Level III as well as equipment for Ultrasonic, Magnetic Particle and Dye Penetrant Tests available in house.

Hydrotesting

Testing upto 40,000 pounds per square inch possible with advanced transducers used for recording the data in form of charts with accuracy upto 1 pounds per square inch.

Open Die Forging

Capacity to forge single part upto 8000 MT with the assitance of 1500 MT hydraulic Press supported by 8MT Manipulator of Zdas Make. (Coming Soon)