Ever since our inception in 1989, we have continuously upgraded our systems and processes to be at the forefront of a fast-evolving forging industry.We use simple but effective techniques to ensure impeccable quality that has become a MARS trademark: a porpitious mix of best-of-breed equipment, highly qualified metallurgists, and extremely skilled technicians.

Our shop floor boasts of some of the most sophisticated manufacturing facilities . Our top-of-the range hammers up to 6.25 tonnes, presses with commensurate capacity, machines for in-house manufacturing of dies, and state-of-the-art facilities for heat treatment, our well-equipped laboratory all work in unison to create the perfect forging for the discerning customer. We forge single piece upto 250 kgs in closed die forigng. We have an annual capacity of 8000 MT.

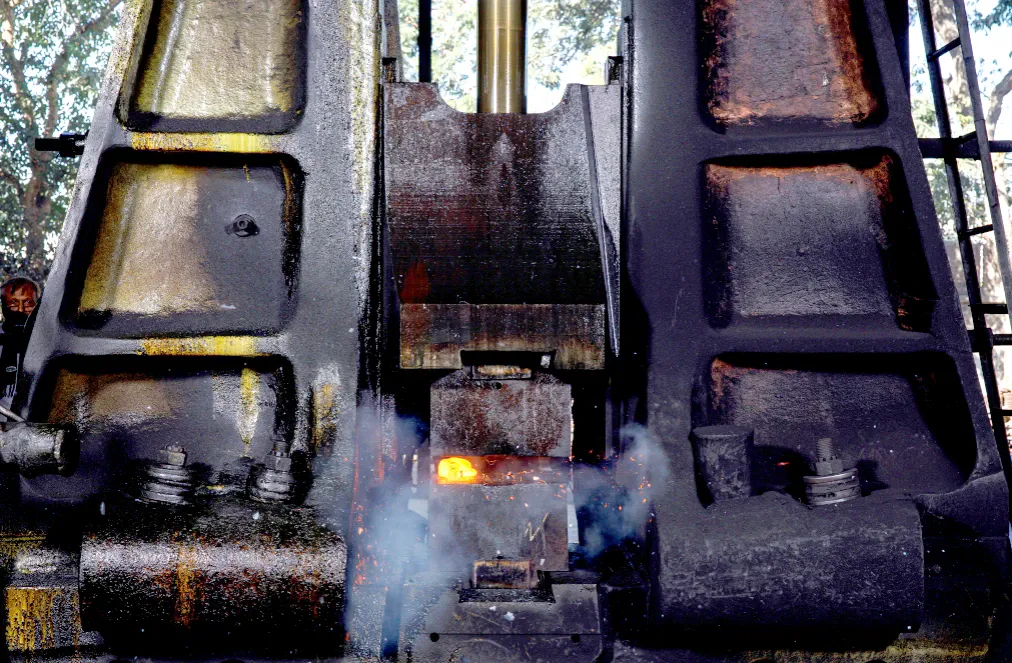

Forge Shop

Forging Hammers

- 6.25 MT Pneumatic Hammer

- 3.0 MT Pneumatic Hammer

- 2.0 MT Mechanical Hammer

Capacity of parts by weight: upto 250 kgs (simple or round jobs) and upto 180 kgs for complex jobs.

Cutting shop

- No. of Bansaws = 12 Nos.

- No. of Shearing Machines = 1 No.

Capacity - upto 125 mm Roughly Cut Square/Billet size

Capacity - upto 500 mm diameter

Die Shop

- Number of Vertical Milling Centres - 2 Nos.

- Number of Conventional Lathes - 4 Nos.

Capacity - Size upto 500 mm diameter and 7 meters of length.

Capacity - Size 900 mm x 1500 mm x 700 mm and weight 15 tonnes.

Heat Treatment

Continuous Gas Fired Furnace with Calibration as per API 6A Annex M Process executed:

- Normalizing

- Quenching (water or oil) and Tempering

- Solution Annealing

Materials Heat Treated: AISI 4130, 4140, 410 (SS), 450 (SS), 316, 316L, 1018, 1010; EN 8, 8D, 9 ; 17-4Ph (precipitation Hardend Steel); 42CrMo4, 40CrMo5, ASTM A105, ASTM A234 etc.

Hardness Test

- Brinell Hardness Tester - 5 Nos.

- Rockwell Hardness Tester - 2 Nos.

- Leeb Hardness Tester - 1 No.

- King’s Hardness Tester - 2 Nos.

Mechanical and Metallurgical Testing

- Tensile Testing Machine

- Charpy Impact Testing as Per ASTM

- Microscope Olympus Make

- V- Notch Testing Automatic Machine

- Macroetch Testing Facility

NDE Testing

Testing Equipments

- Ultrasonic Testing Machine - 1 No.

- Magnetic Particle testing Machine - 2 Nos.

- Dye Penetrant Testing Room - 1 No.

Inhouse Testing Personnel

- NDT Level II Personnel - 3 Nos.

- NDT Level III Personnel - 1 No.

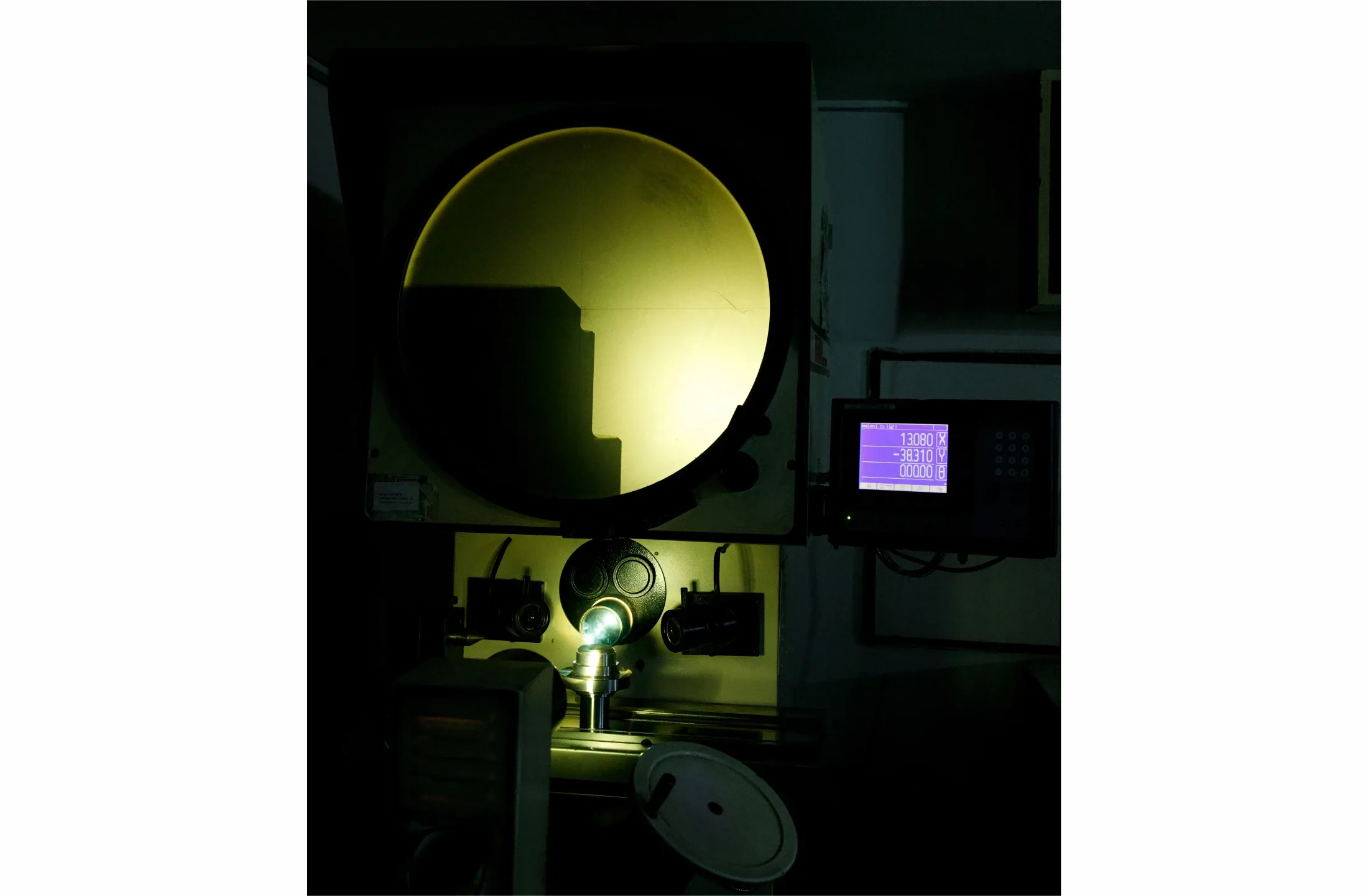

Metrological Testing Facility

- Profile Projector with Data Recorder

- Gagemaker Calibration Equipment

Height Gauges and other thread gauges approved and traceable to API 5B masters.

Mitituyo make verniers and micrometers upto 1000 mm measurement range.

Machine Shop

HMC Machines - 2 Nos

- Twin Pallet upto 500 mm x 500 mm table size

- MoriSeiki Make

CNC Machines - 14 Nos.

- Maximum turning Diameter - upto 600 mm

- Maximum Length - upto 1.5 meters

- Through Spindle Bore - upto 160 mm diameter

VMC Machine - 3 Nos.

- 3 axis and 5 axis machines available

Packing Shop

- Laser Marking Machine

- Paint Shop

- Bucking Machine

Hydrotest Facility

Capacity to hydro test up to 40,000 PSI test Pressure rating with transducer and electronic data logging that provides pressure readings with the least count of 1 PSI with pressure charts.

Open Die Forging

1500 MT Hydraulic Press with an 8MT Zdas Make Manipulator with a capacity to open forge single piece up to weight range of 8MT.